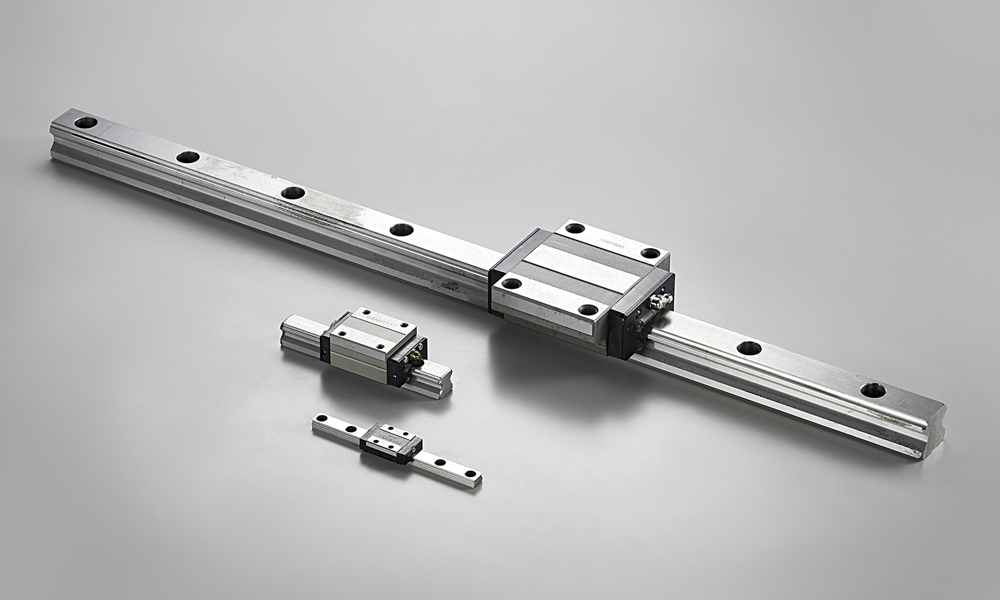

In high-precision industries, performance and reliability are crucial. Engineers and manufacturers consistently seek components that can withstand demanding conditions while maintaining accuracy. One essential component in this pursuit is the LM slide bearing (ลูกปืนสไลด์ LM, which is the term in Thai). Known for its durability and precision, it plays a pivotal role in applications ranging from robotics to heavy machinery.

Why LM Slide Bearings Are Exceptional

LM slide bearings are engineered to reduce friction and facilitate smooth, linear motion. Their compact design combines efficiency and strength, making them ideal for high-stress environments. Crafted with advanced materials, these bearings endure heavy loads while maintaining low wear, ensuring consistent performance over time.

Key Benefits:

- Precision Engineering: Designed with tight tolerances, LM slide bearings offer impeccable accuracy, crucial for applications requiring exact positioning.

- Long-Lasting Durability: Manufactured with high-grade materials, they resist wear and tear, even under continuous use.

- Versatility: Suitable for industries such as aerospace, automotive, and manufacturing.

Their capacity to handle dynamic movements while maintaining stability sets them apart from traditional bearings. This makes them a preferred choice in high-precision environments where error margins are minimal.

Applications of LM Slide Bearings

The versatility of LM slide bearings is evident in their widespread use. These bearings are indispensable in the following ways:

- CNC Machinery: Providing accurate and fluid movement for cutting and shaping materials.

- Medical Equipment: Ensuring reliability in devices such as imaging machines and robotic surgical tools.

- Automation Systems: Supporting repetitive motion in robotic arms and conveyor systems.

- Aerospace Technology: Offering high precision in systems exposed to extreme conditions.

These applications highlight the necessity of a component capable of maintaining smooth operation under rigorous demands.

Maintenance Tips

To ensure optimal performance, proper maintenance is critical.

- Regular Lubrication: Use recommended lubricants to minimize wear and friction.

- Routine Inspections: Check for misalignments or debris that could hinder performance.

- Clean Environment: Avoid exposure to excessive dust or contaminants.

Adhering to these practices extends the lifespan of the bearings and ensures consistent functionality.

Final Thoughts

In industries where precision and reliability are non-negotiable, LM slide bearings prove to be invaluable. Their robust design and adaptability make them a cornerstone of high-performance machinery. By investing in these bearings, manufacturers can enhance efficiency and reduce operational downtimes.