When it comes to the function implementation of electronic items, the printed circuit board (PCB) is critical. The PCB is known as the brain of electronics; it informs electricity where to function and how to connect electricity parts to circuit boards and other electronic elements.

Because of its stable political climate, favorable national rules, abundant natural resources, growing global impact, and people resources, China is without a doubt one of the most prolific economies in the world when it comes to electronics manufacture. Nonetheless, this eastern country with extensive old documents appears to be a little different from what people have been imagining, which often leads to misconception. As a result, it is critical for international clients to understand more about “Chinese characteristics” on China PCB service, which enables you to make better use of China’s assets that contribute to high-quality electronics manufacturing for key benefit fulfillment based on electronic products.

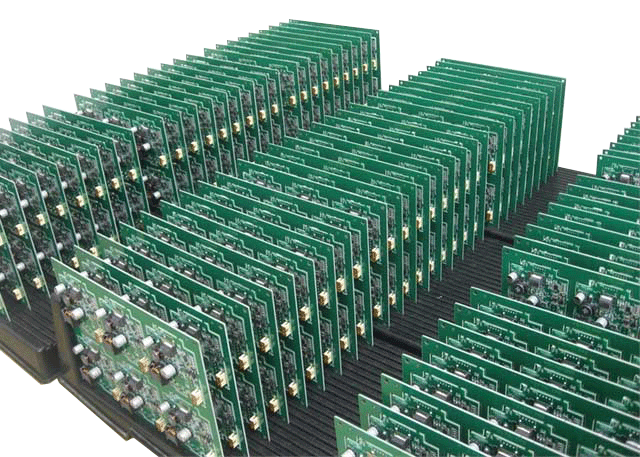

Assembly of Printed Circuit Boards

PCB assembly follows PCB fabrication, with current factors sourcing implemented. PCB assembly enhances the connection range of printed circuit boards with PCB service components in a similar way. SMT (surface mount technology) assembly, which is an automatic manufacturing line with high assembly productivity, has been the most popular PCB assembly type until now.

The Standard Procedure for Obtaining China PCB Service

Increasing the utilization of China PCB service is similar to opening Pandora’s Box. China not only offers incredible advantages in terms of electronics manufacturing, but it also adheres to high-quality trade policies all over the world. It will be simple to keep ahead of China PCB service if you follow the steps below.

The first step is to convert an idea into a PCB design file.

Your creativity plane begins to parachute as soon as your viewpoint is converted into a PCB design file. In PCB design, flexibility is a crucial component and stage. It is more effective to provide your CAD (computer-aided design) report in place of Gerber extended document alone to protect your PCB layout files from dangers that may cause disagreement between two counterparts, you (customers) and PCB manufacturers, because separate variations of Gerber document readers may result in records missing or errors.

Step 2: Find a reputable and dependable China PCB manufacturer.

There are numerous methods for evaluating a PCB manufacturer. This stage is difficult to obtain a China PCB service since you will be presented with numerous possibilities and may become confused. You’ve already completed half of your PCB service by selecting a reputable PCB manufacturer.

Step 3: Submit the prototype PCB assembly order.

Your right hand holds a reputable China PCB manufacturer, while your left hand holds your PCB layout file. This is the ideal time to start working on your PCB service. After you’ve given your PCB design file to your contract manufacturer or assembler, you’ll receive a quote depending on the circuit complexities and scope of your request.

Step 4: Verify the prototypes’ functionality and quality.

When it comes to layout and order, it’s a good idea to use prototypes to test the correctness and smooth operation of your circuit design before going into mass production. It is not necessary to complete prototype service when it comes to PCB reordering. However, even if your PCB design changes, the PCB prototype remains a crucial operation.

Step 5: Submit the order for mass and quantity.

After your PCB prototypes have been thoroughly checked for flaws, mass-quantity manufacture can begin. It’s either an email order or an online order, depending on your cooperative PCB manufacturer’s service stage and habit. Of course, in terms of PCB service online, the former is more productive.

ChinaPCBOne Technology LTD. is the author of this article on China PCB. Find more information, about PCB manufacturer.