Stainless steel has long been known for its durability, corrosion resistance, and aesthetic appeal. Technological advancements have recently introduced innovative methods for enhancing stainless steel’s visual and functional properties. One such technique gaining prominence is laser etching. This article delves into the various benefits of laser etching on stainless steel, exploring how this precise and versatile process revolutionises various industries.

1.) Precision and Detail

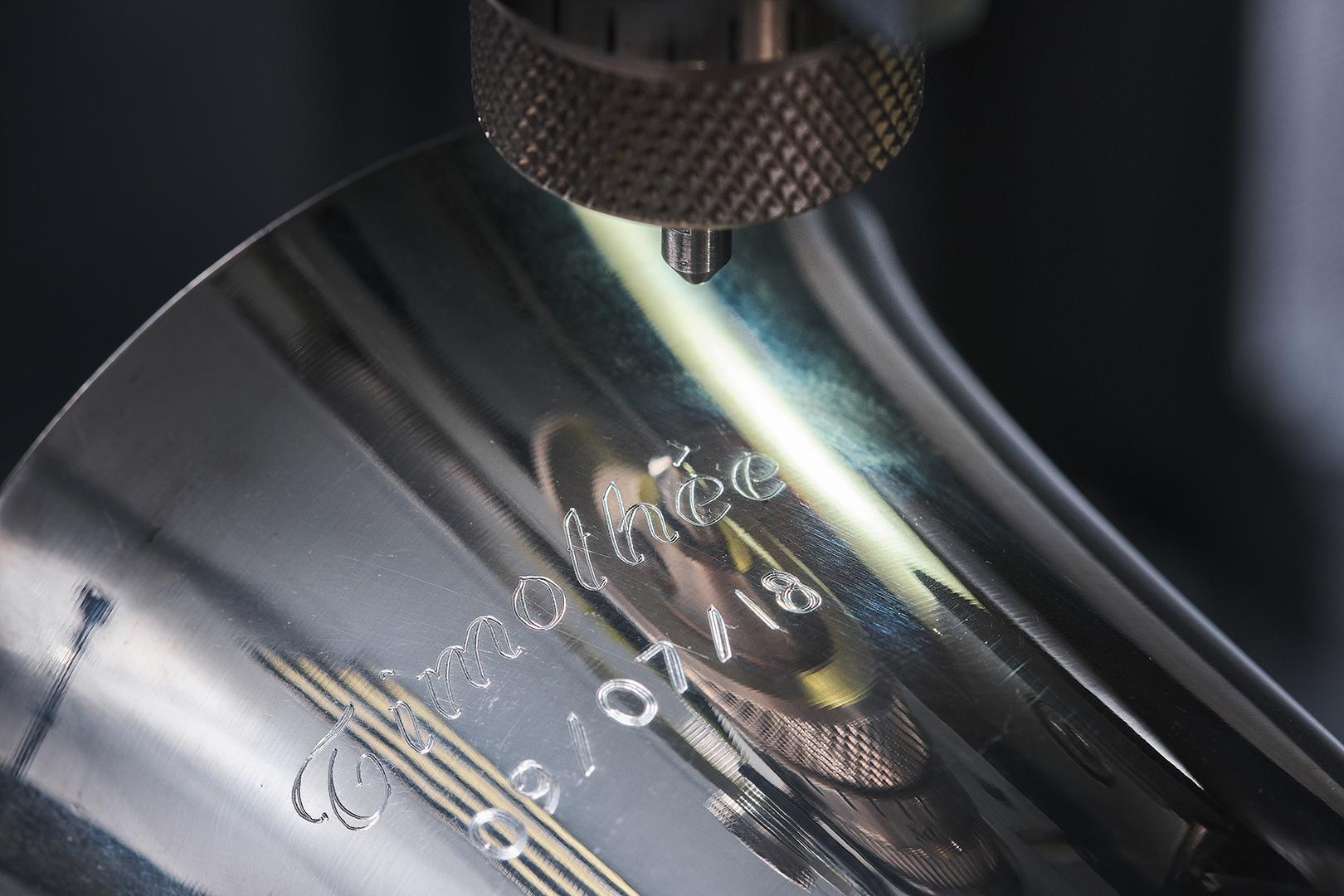

At the heart of laser etching’s appeal is its unparalleled precision. Laser systems can achieve intricate detailing and fine lines with remarkable accuracy, allowing for the creation of complex and visually stunning designs on stainless steel surfaces. This precision is especially advantageous for applications such as product branding, signage, and decorative elements, where intricate details and crisp lines are crucial.

2.) Durability and Permanence

Laser etching on stainless steel offers unparalleled durability. The process creates permanent marks resistant to wear, fading, and environmental factors. Unlike traditional methods such as printing or the common one of engraving, laser etching ensures that the design becomes an integral part of the stainless-steel surface, making it resistant to scratching, peeling, or degradation over time.

3.) Versatility in Material Compatibility

Another significant benefit of laser etching on stainless steel lies in its versatility. This method is compatible with various grades and finishes of stainless steel, offering a wide range of options for different applications. Whether it’s a polished, brushed, or matte surface, laser etching can be adapted to suit the specific characteristics of the stainless-steel substrate.

4.) High-Speed Processing

Laser etching is known for its efficiency and speed. The process allows for rapid marking and etching on stainless steel surfaces, making it an ideal choice for industrial applications where high production rates are essential. This speed enhances productivity and contributes to cost-effectiveness, making laser etching a preferred choice for manufacturers and businesses.

5.) Non-Contact Process and Minimal Material Distortion

Laser etching is a non-contact process, unlike traditional methods involving physical contact with the material. This minimises the risk of material distortion or damage during the marking process. The lack of physical force reduces the likelihood of scratches or dents on the stainless-steel surface, ensuring a pristine and flawless final product.

6.) Environmentally Friendly

Laser etching is an environmentally friendly process, generating minimal waste compared to some traditional methods. It eliminates the need for consumables such as inks or chemicals, contributing to a cleaner and more sustainable manufacturing process. Additionally, the precision of laser etching minimises the chances of errors or rework, further reducing material waste.

7.) Wide Range of Applications

The versatility of laser etching on stainless steel opens the door to a wide application. The possibilities are vast, from industrial part marking and medical equipment identification to artistic expressions and personalised products. The ability to precisely mark text, graphics, and even barcodes make laser etching an invaluable tool across diverse industries.

Conclusion

In conclusion, the benefits of laser etching on stainless steel are transforming the way we approach surface marking and design. Precision, durability, and versatility make laser etching a leading choice for industries seeking high-quality, permanent, and visually striking results. Artcom Fabrication is a well-known company that specialises in designing and manufacturing laser etching and CNC routing services in Perth! Connect with them to learn more about their services.